Quality Assurance Testing

Real, Quality Products

Through our stringent quality control processes, NAI is committed to providing our clients with quality dietary supplements and assurance that the products they are putting into the market are safe and beneficial.

How we do it

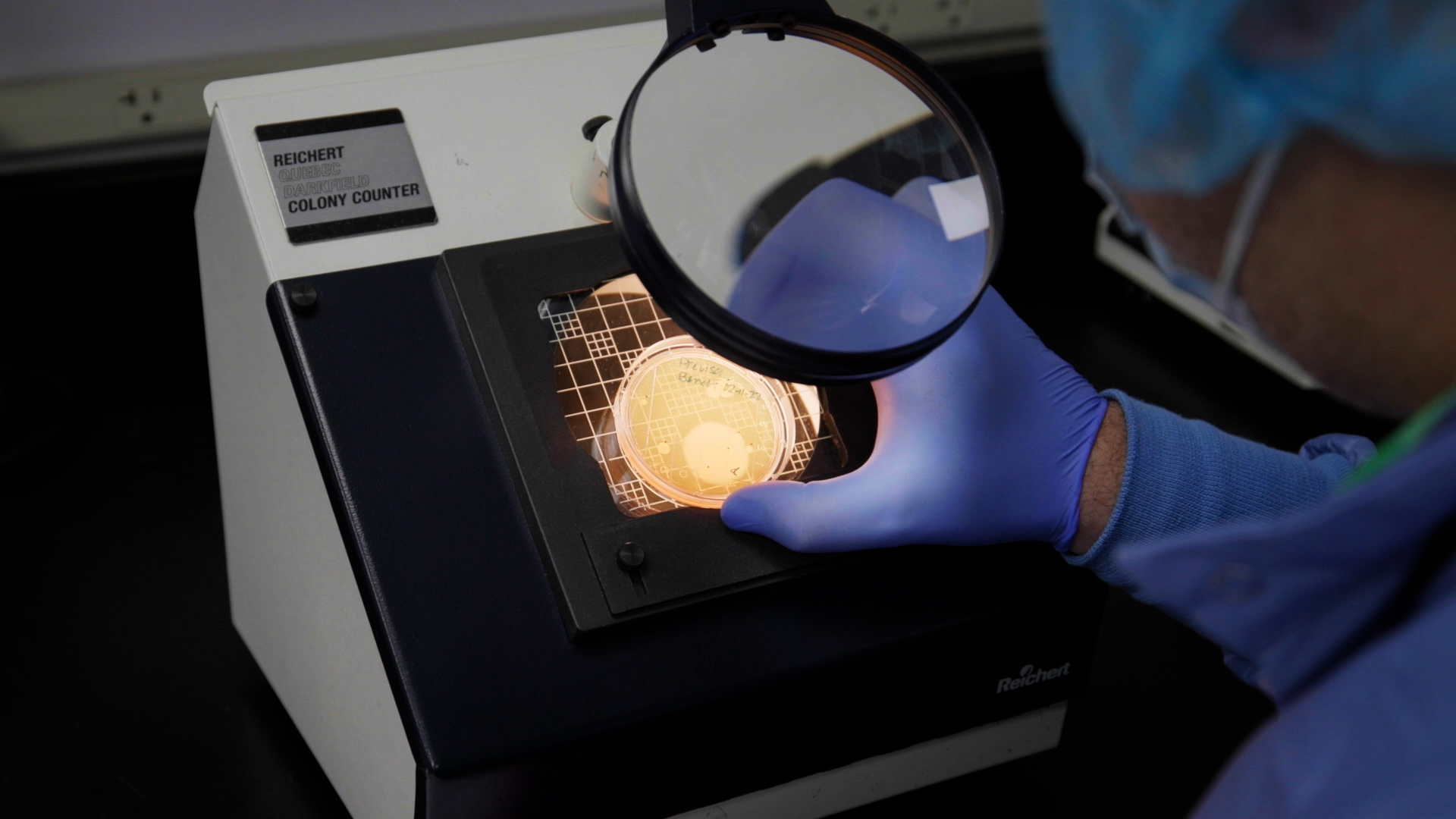

Our comprehensive infrastructure enables us to tightly control every step of the manufacturing process, allowing us to ensure that quality is never sacrificed. Our onsite laboratory continuously monitors the output of the production facilities to ensure the highest quality of finished goods. We conduct extensive laboratory testing on the industry standard for state-of-the-art laboratory equipment. All products are meticulously examined for weight, ingredient homogeneity, color standardization, and content levels. Tablets are tested for hardness, thickness, dissolution, and integrity.

Raw Material Testing

NAI certifies that each raw material used meets or exceeds the requirements upheld by the U.S. Food and Drug Administration (FDA), the U.S. Pharmacopoeia (USP) and the Therapeutic Goods Administration of Australia (TGA) and Prop 65. NAI maintains a retention room where samples of product, Certificates of Analysis and identification of vendors and lot numbers for raw materials are stored for a minimum of five years, enabling us to trace the source of every element of every product.

State-of-the-Art Equipment

- High-Performance Liquid Chromatography (HPLC)

- Inductively Coupled Plasma Emission Spectrophotometry (ICP)

- Dissolution and Absorption

- Microbiological Testing

- Fourier Transform Near Infrared Spectroscopy (FT-NIR)

International Compliance

NAI maintains compliance with both USP and Good Manufacturing Practices (GMP) for food, drugs and cosmetics, which are used internationally to ensure that products manufactured under these strict guidelines fulfill required standards of quality for nutraceutical products.

Real, Quality Products

Through our stringent quality control processes, NAI is committed to providing our clients with quality dietary supplements and assurance that the products they are putting into the market are safe and beneficial.

How We Do It

Our comprehensive infrastructure enables us to tightly control every step of the manufacturing process, allowing us to ensure that quality is never sacrificed. Our onsite laboratory continuously monitors the output of the production facilities to ensure the highest quality of finished goods. We conduct extensive laboratory testing on the industry standard for state-of-the-art laboratory equipment. All products are meticulously examined for weight, ingredient homogeneity, color standardization, and content levels. Tablets are tested for hardness, thickness, dissolution, and integrity

Raw Material Testing

NAI certifies that each raw material used meets or exceeds the requirements upheld by the U.S. Food and Drug Administration (FDA), the U.S. Pharmacopoeia (USP) and the Therapeutic Goods Administration of Australia (TGA) and Prop 65. NAI maintains a retention room where samples of product, Certificates of Analysis and identification of vendors and lot numbers for raw materials are stored for a minimum of five years, enabling us to trace the source of every element of every product.

State-of-the-Art Equipment

- High-Performance Liquid Chromatography (HPLC)

- Inductively Coupled Plasma Emission Spectrophotometry (ICP)

- Dissolution and Absorption

- Microbiological Testing

- Fourier Transform Near Infrared Spectroscopy (FT-NIR)

International Compliance

NAI maintains compliance with both USP and Good Manufacturing Practices (GMP) for food, drugs and cosmetics, which are used internationally to ensure that products manufactured under these strict guidelines fulfill required standards of quality for nutraceutical products.